FIBC Structure

Body Structure - Basic

The bag's body is categorised into three structural types, defined by its method of assembly and distinguished by unique characteristics and functions.

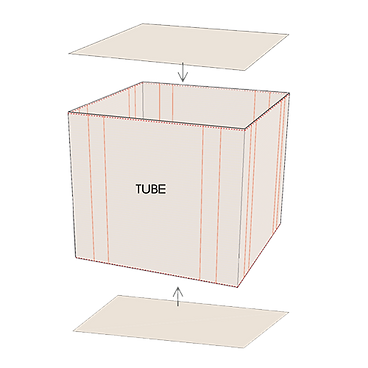

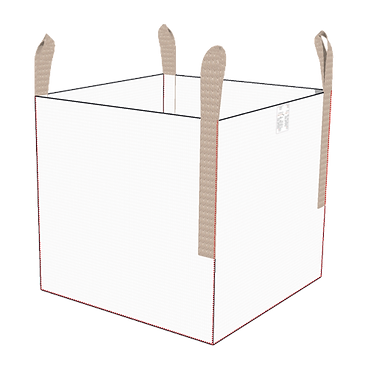

Tube Type

The body consists of a cylindrical tube of fabric, with separate fabric panels attached to the top and bottom to create the tone bag.

This is a common design. When the tone bag is filled, the cylindrical body expands and rounds out.

Typically, the top and bottom panels are square, which means the shape is not a perfect cylinder. However, in some cases, circular panels are used instead, resulting in a complete cylindrical form.

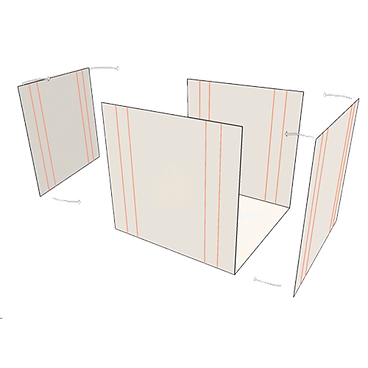

U-Panel Type

This structure is referred to as four-sided sewing because stitching is applied along all four corners. It maintains a more defined square shape when filled compared to the tubular type, though it still isn't a perfect square.

The body is formed by folding the fabric into a U-shaped panel, with additional fabric pieces attached to the sides to create the body and bottom of the ton bag.

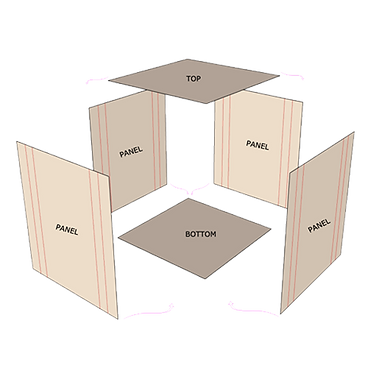

4-Panel Type

This design is known as four-panel sewing because all four corners are stitched. It holds a squarer shape when filled compared to the tubular type, though it still doesn't form a perfect square.

Four separate fabric panels are joined to construct the body, with additional panels attached to the top and bottom to complete the ton bag.

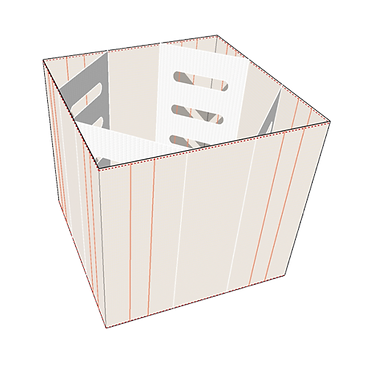

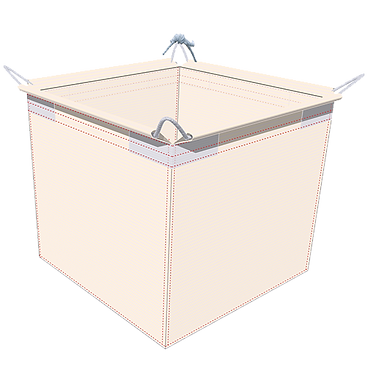

Baffle Type

Baffles are sewn into the interior of the bag to help it maintain a perfectly square shape, even when filled.

Square-shaped packaging allows bags to be stacked closely together without wasted space, making baffled ton bags especially suitable for storage in confined areas such as containers and cargo trucks.

Lifting Structure

The lifting loop is used to attach the ton bag to equipment like a forklift or crane, allowing the bag and its contents to be moved safely and efficiently.

Cross Corner Belt

A flat belt, typically 70mm to 100mm wide, is attached to all four top corners of the ton bag. The eight connection points on the body fabric where the belts are secured are double-woven to enhance strength and ensure safety.

This design is compatible with all body types, including tubular, four-panel, and baffled structures.

Side Seam Belt

The belt is sewn along the four corners of the ton bag, similar to how the body panels are joined.

It attaches to the body at four points, following the seams along the sides.

This type of belt is not used with tubular designs but is suitable for four-panel sewn and baffled bags.

Lifting Rope

A polypropylene (PP) rope, typically 12mm to 16mm thick, is used for the lifting hooks.

In addition to providing lifting support, the rope helps slightly tighten the top of the ton bag when lifted.

Due to its greater thickness and the inherent durability of the material, this type of hook is recommended for environments where hooks are more prone to damage.

Superstructure

Open Type

The top of the ton bag is fully open, without a cover or filling spout.

This open-top design is ideal for quickly loading large volumes of material, such as when using a forklift to scoop soil.

Spout Type

A ton bag equipped with a spout for filling. The spout serves as the entry point and can be shaped like a duffel, O, X, or Ω (Omega).

A duffel spout resembles a skirt-like cover attached around the top of the bag, matching the body’s circumference.

The O, X, and Ω-shaped spouts are designed with diameters that fit into a hopper. The bag’s contents are discharged through the hopper—a funnel-shaped device on the filling machine—so these spouts are tailored to match the hopper for easy filling.

The cover shape that seals the spout after tying is also referred to as O, X, or Ω type, corresponding to the spout design.

Infrastructure

Close Bottom

The bottom of the ton bag is sealed and designed to hold materials that do not require discharge from the base, such as soil or waste used in water barriers.

If necessary, a hole can be cut in the bottom for discharge, but this practice is generally discouraged due to safety concerns.

Bottom Spout Type

A ton bag equipped with a spout for filling. The spout serves as the entry point and can be shaped like a duffel, O, X, or Ω (Omega).

A duffel spout resembles a skirt-like cover attached around the top of the bag, matching the body’s circumference.

The O, X, and Ω-shaped spouts are designed with diameters that fit into a hopper. The bag’s contents are discharged through the hopper—a funnel-shaped device on the filling machine—so these spouts are tailored to match the hopper for easy filling.

The cover shape that seals the spout after tying is also referred to as O, X, or Ω type, corresponding to the spout design.